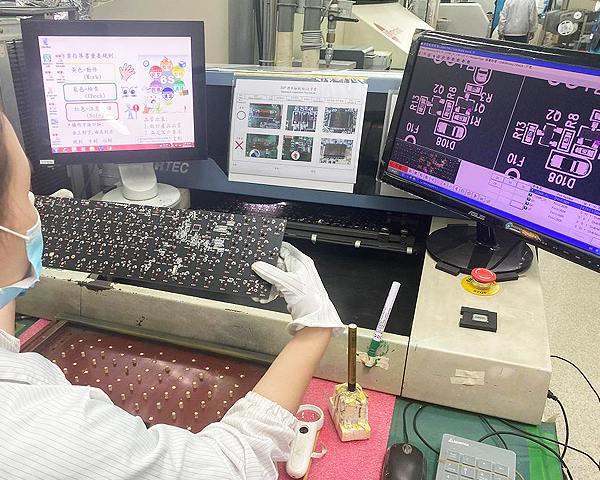

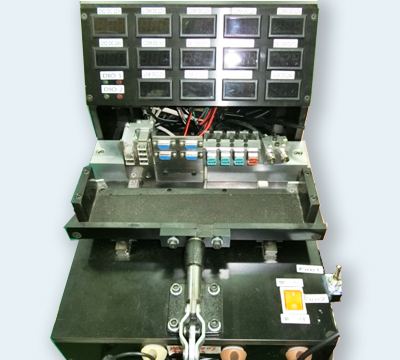

One production line each for the plug-in and

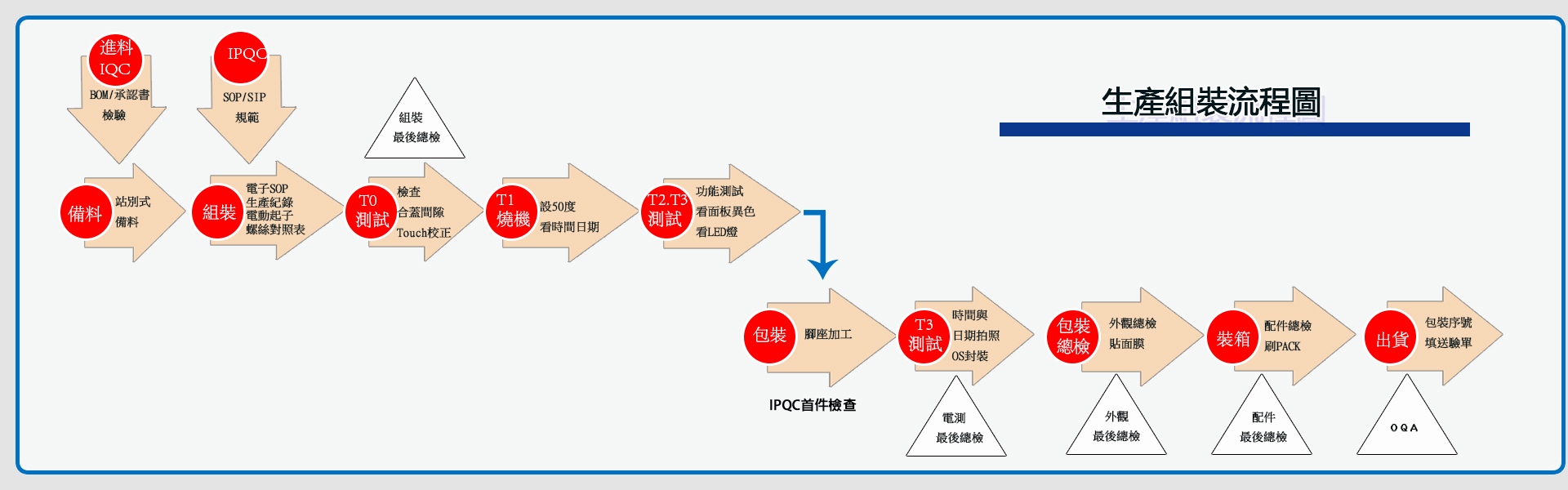

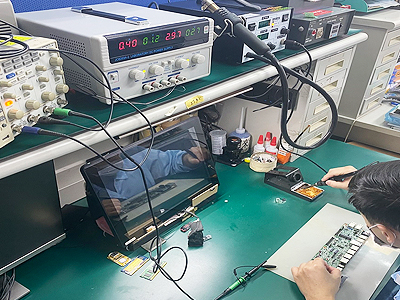

assembly

packaging, respectively; the operation is based on the actual needs of customers

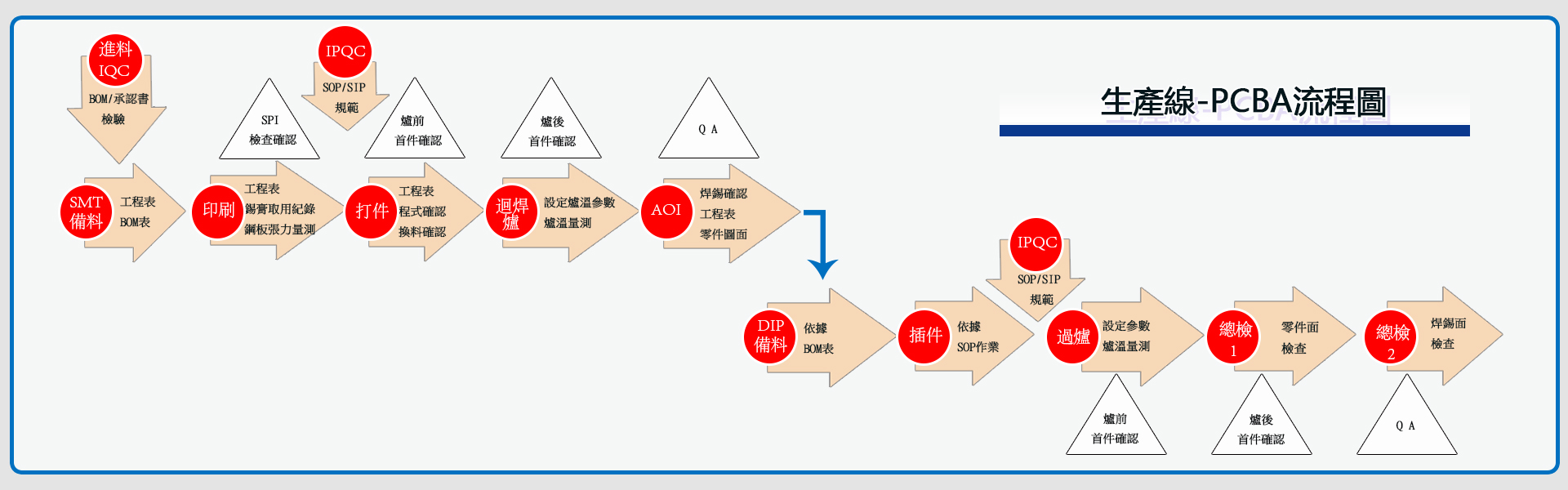

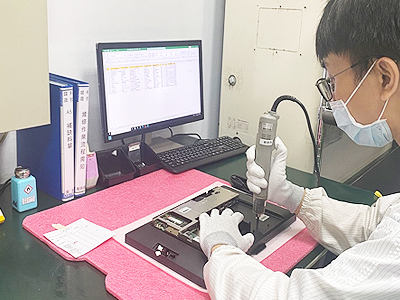

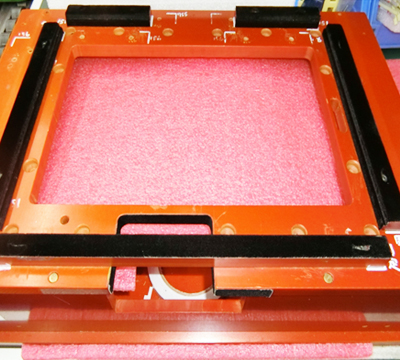

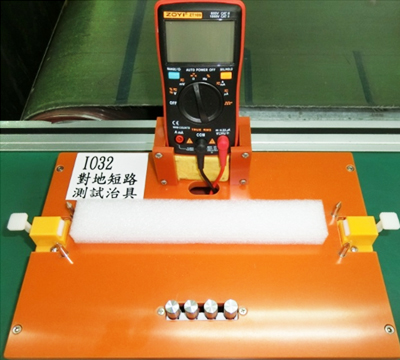

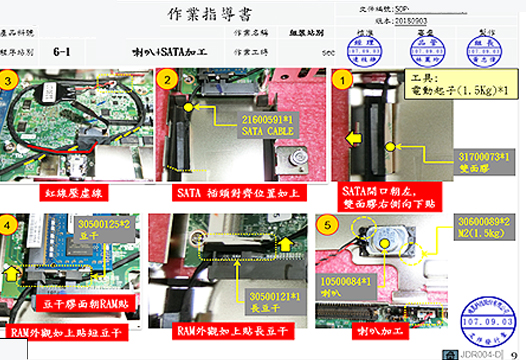

Cutting board → plug-in → tin furnace → tin surface trimming → testing →

assembly → packaging